Voyager 315 Nitrox Generation System

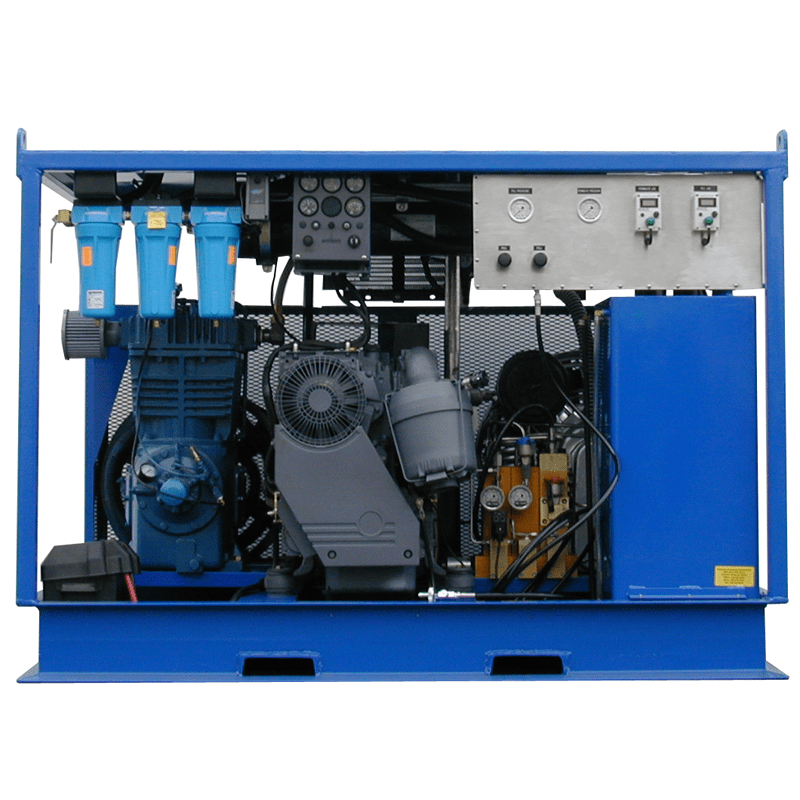

The Nuvair Voyager 315 Nitrox System is a turnkey package that produces oxygen rich air (nitrox) and compresses the nitrox mixture with a high pressure (HP) compressor to fill scuba tanks or storage cylinders. The package is designed to be fully automatic, with a quieted enclosure for noise reduction and protection from moving parts while it is running. Its modular, two-part cabinet system fits through most doorways.

The Nuvair Voyager 315 uses a rotary screw low pressure (LP) compressor, air aftercooler, refrigerated air dryer (or optional volume tank), and filtration to provide the membrane system with a source of clean, pressurized feed air for separation. The air is filtered to CGA Grade D or better air quality prior to entering the membrane system so it will not damage or plug the membrane fibers. Specifications for Grade D air are provided in the appendix of the Voyager 315 User Manual.

The Voyager 315 allows for efficient and cost effective nitrox production using electric power without the hazards or expense of blending with stored high-pressure oxygen (O2). The Voyager 315 membrane system is rated for a maximum feed air pressure of 300 psi (21 bar) and has been configured to work well with the 175 psi (12 bar) maximum pressure delivered by the LP compressor. A feed air pressure regulator reduces the pressure to appropriate levels for various oxygen percentages in the enriched air nitrox (EANx) production. The air is then heated to a temperature that provides stability over a wide range of ambient conditions, is optimal for membrane permeation, and prevents moisture condensation.

The heated air enters the membrane, which is made up of thousands of miniature hollow fibers. The walls of these fibers are semi-permeable and designed for different gases to move through them (or permeate) at different speeds. The resulting gas mixture is known as the "permeate." As air flows through the hollow fibers, both oxygen and nitrogen permeate through the fiber walls. The oxygen permeates faster than the nitrogen, which produces permeate with an oxygen content greater than air.

The gas that reaches the end of the hollow fibers without permeating is almost entirely nitrogen and is discharged. The flow rate of this discharge is set by the factory via a fixed orifice, which controls the permeate to contain a constant 44% oxygen (EANx44) under normal operating conditions. The permeate is a concentrated mixture that must be diluted with additional air prior to entering the high-pressure (HP) compressor. It exits the membrane at ambient to slightly negative pressure and travels into the mixing tube, where it mixes homogeneously with filtered outside air.

The amount of dilution—and thus the final percentage of oxygen in the nitrox blend—is obtained by adjusting the feed air pressure regulator. As pressure is increased, permeate flow increases, air flow decreases, and a higher percentage of oxygen in the nitrox mix is produced. As pressure is decreased, permeate flow decreases, air flow increases, and a lower percentage of oxygen in the nitrox blend is produced. This relationship between permeate flow and air flow exists because the total of these two flow rates will always equal the intake flow rate demanded by the HP compressor. The resulting nitrox mixture is analyzed for oxygen percentage before entering the HP compressor for approximate content and again when pumping nitrox for precise content. The HP compressor pumps the nitrox to a maximum pressure of 3600 psi (250 bar) to fill scuba tanks or storage cylinders.

A unique feature of Nuvair Nitrox Systems is that the feed air pressure that correlates to a specific nitrox oxygen percentage is repeatable. For example, if your HP compressor pumps EANx36 when the feed air pressure is at 125 psi (9 bar), adjusting the feed air pressure regulator to 125 psi (9 bar) during the next use will produce the same mixture. Although it is described as a "nitrox compressor," it can also be used to pump air.

Features

- Fully Featured for Automatic Operation

- Enclosed and Silenced Cabinet

- Modular, Two-Part Cabinet System Fits Through Most Doorways

- 10 CFM Nuvair Membrane System

- Ingersol Rand EK76 Rotary Screw LP Compressor

- Pump Rated at 29 ACFM @ 175 psi for Membrane Supply

- High Quality 10 hp Electric Motor - Three-Stage High Pressure Compressor

- Pumps Air to 4500 psi (310 bar); Nitrox to 3600 psi (250 bar)

- Pump Rated at 10.6 CFM

- High Quality 7.5 hp Electric Motor - Two (2) Pro O₂ analyzers (one permeate and one fill oxygen analyzer)

- Hankison 3-Stage LP Air Filtration

- One (1) CAN-35 Filtration Tower processes 26,000 ft³ of Grade E air

- Automatic Dial-a-Pressure Shutdown

- Automatic LP/HP Condensate Drains

- Cabinet Temperature Gauge

- Push Button On/Off Motor Starters

- LP and HP Hour Meters

- External Oil Sight Gauge, Fill and Drain

- Cooling Fans

- Refrigerated Air Dryer

- High Cabinet Temperature Shutdown

Advantages

- Complete state-of-the-art LP/HP nitrox generating system

- Pump HP air or nitrox containing up to 40% oxygen (EANx40) at 10 CFM

- None of the costs, hassles, or hazards of oxygen blending

- Simplest, most cost-effective solution available

- Semi-silenced enclosure reduces operating noise

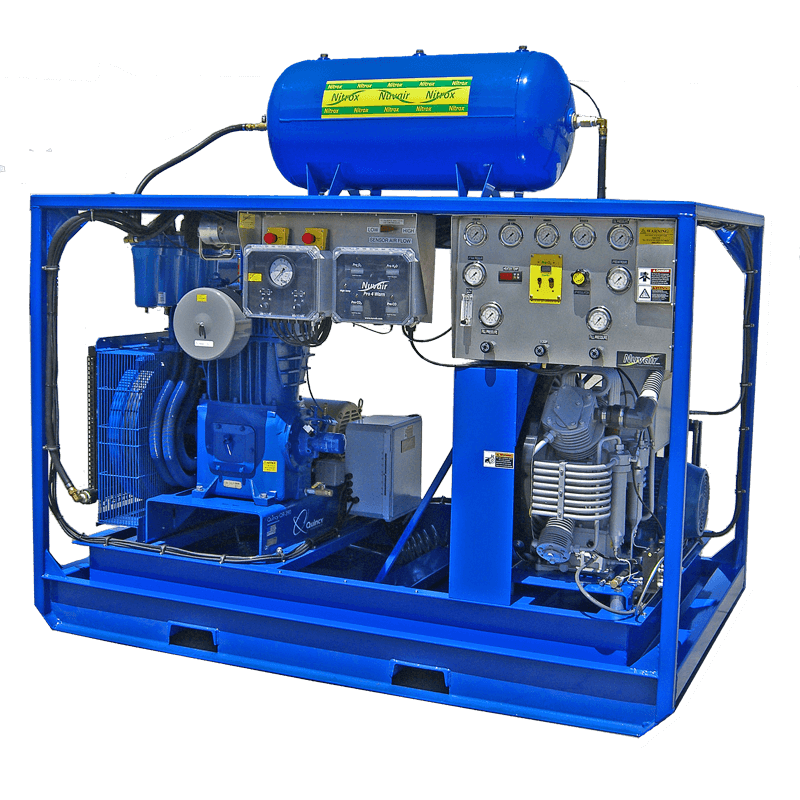

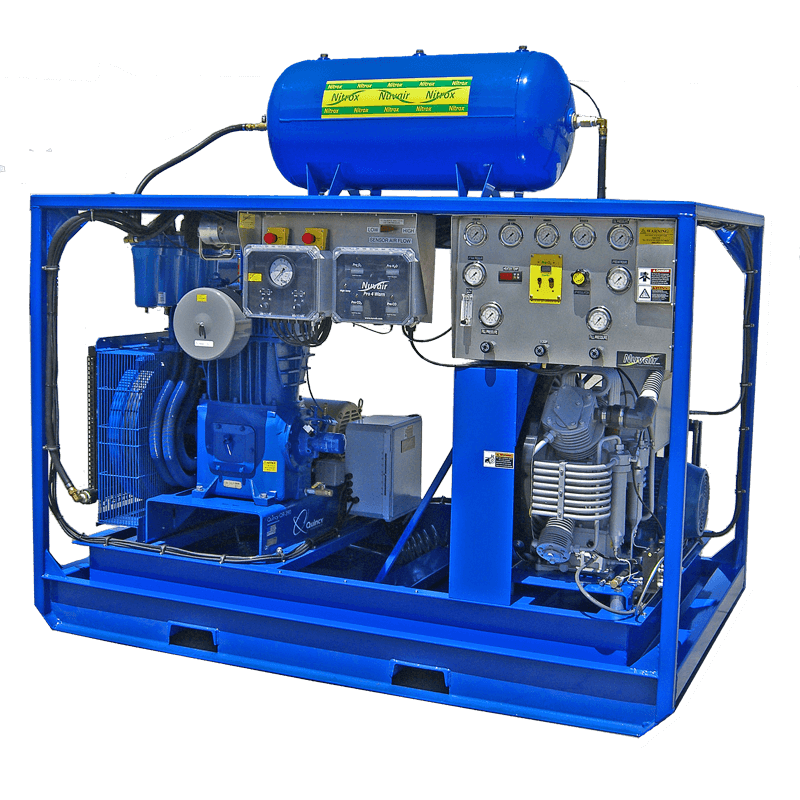

Options

- CO₂ Scrubber (SKU 6070.5, as pictured)

- Standalone Volume Tank in Lieu of Refrigerated Air Dryer

- Second CAN-35 Filtration Towers (as pictured)

- Pro H₂O (moisture), Pro CO (carbon monoxide), and/or Pro CO₂ (carbon dioxide) analyzers (As pictured: Pro CO and Pro CO₂ installed)

- Electrical supply options to meet local requirements · 208-230V/E1-3/50-60Hz, 380-415V/E1-3/50 Hz, or 440-480V/E3/60Hz

Specifications

| Modular Cabinet Specifications | Overall Size | 41.59 x 56.12 x 67.0" (105.6 x 142.5 x 170.2 cm) |

|---|---|---|

| L x W x H | Main Cabinet Housing | 41.59 x 33.84 x 66.81" (105.6 x 86.0 x 169.7 cm) |

| Rear Equipment Stand | 42.0 x 34.0 x 67.0" (106.7 x 86.4 x 170.2 cm) |

|

| LP Flow Rate | 33 CFM @ 100 psi | 31 CFM @ 150 psi |