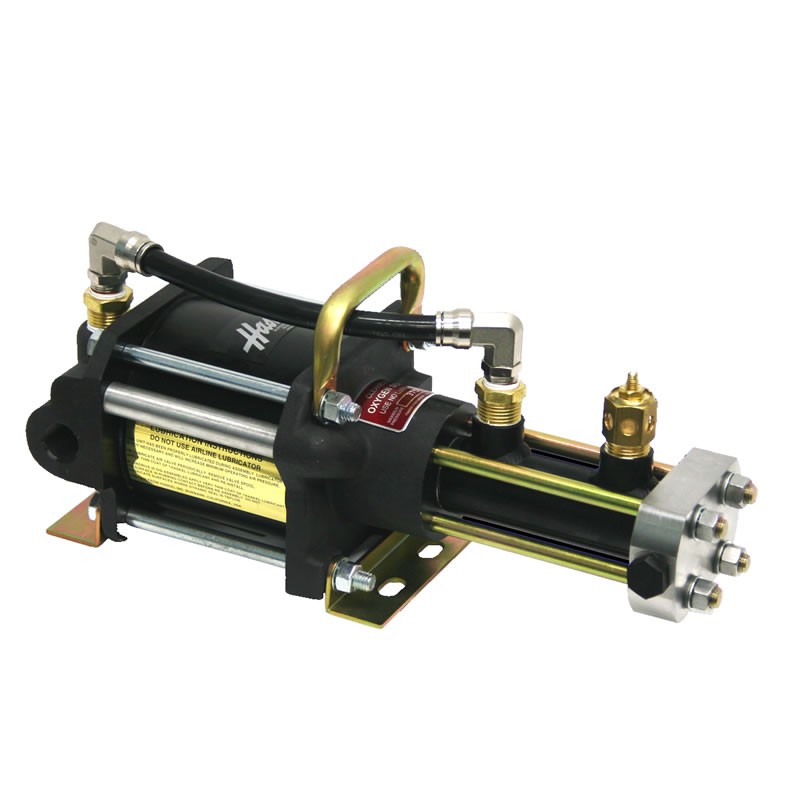

Haskel Air Driven Oxygen Booster

Filling aircraft on-board oxygen cylinders for commercial, military and private fleets. Transferring oxygen into various high pressure receivers for deep ocean diving support, commercial or military. These are just two examples of the uses for the Haskel Air Driven Oxygen Booster Model 26968. In stock ready for delivery.

The 26968 booster system uses the two stage AGT-15/30 booster which allows for low inlet pressure and still delivers volume at high pressure. Conventional industrial, shipboard or contractor type compressed air sources are normally used for power. All motive power and controls are completely pneumatic with no electrical connections required.

Commercial, Military and Private Life Support

The Haskel Air Driven Oxygen Booster Model 26968 is designed for filling oxygen cylinders for use in commercial and military scuba diving applications, but there are broader applications in the transferring of oxygen into various high pressure receivers in many industrial applications.

The 26968 booster system uses the two-stage AGT-15/30 booster which allows for low inlet pressure and still delivers volume at high pressure. Conventional compressed air sources are used for all power and control. No electrical connections are required.

A pneumatic control package continually monitors both inlet cylinder pressure and outlet receiver pressure, stopping the booster automatically when desired outlet or minimum inlet pressure is reached, thus permitting unattended operation.

Features

- Drive is a low friction, slow speed cycling air cylinder, designed for continuous duty without airline lubrication. Vented distance pieces insure hydrocarbon-free gas section operation. High pressure oxygen seals are wear compensating, immune to sudden failure and operate completely non-lube, oil free.

- Very cold air (as low as -20ºF) is a natural byproduct from the air powered drive exhaust. This frigid exhaust air is channeled through a system of cooling jackets and interstage cooler, resulting in high pressure cylinder temperatures well below limits needed for long life of critical parts.

- Inlet gas supply pressure acts directly through the opposed piston construction to assist the air drive during the compression stroke, conserving power required by the drive in direct proportion to the gas supply pressure.

Highlights

- Booster: Air driven, balanced opposed piston type, two stage.

- High Pressure Oxygen Chambers: Non-lube, hydrocarbon-free, triple sealed and vented from the drive air chest.

- Air Drive Section: No oiling required, corrosion resistant factory lubed at assembly, 150 PSI max drive pressure.

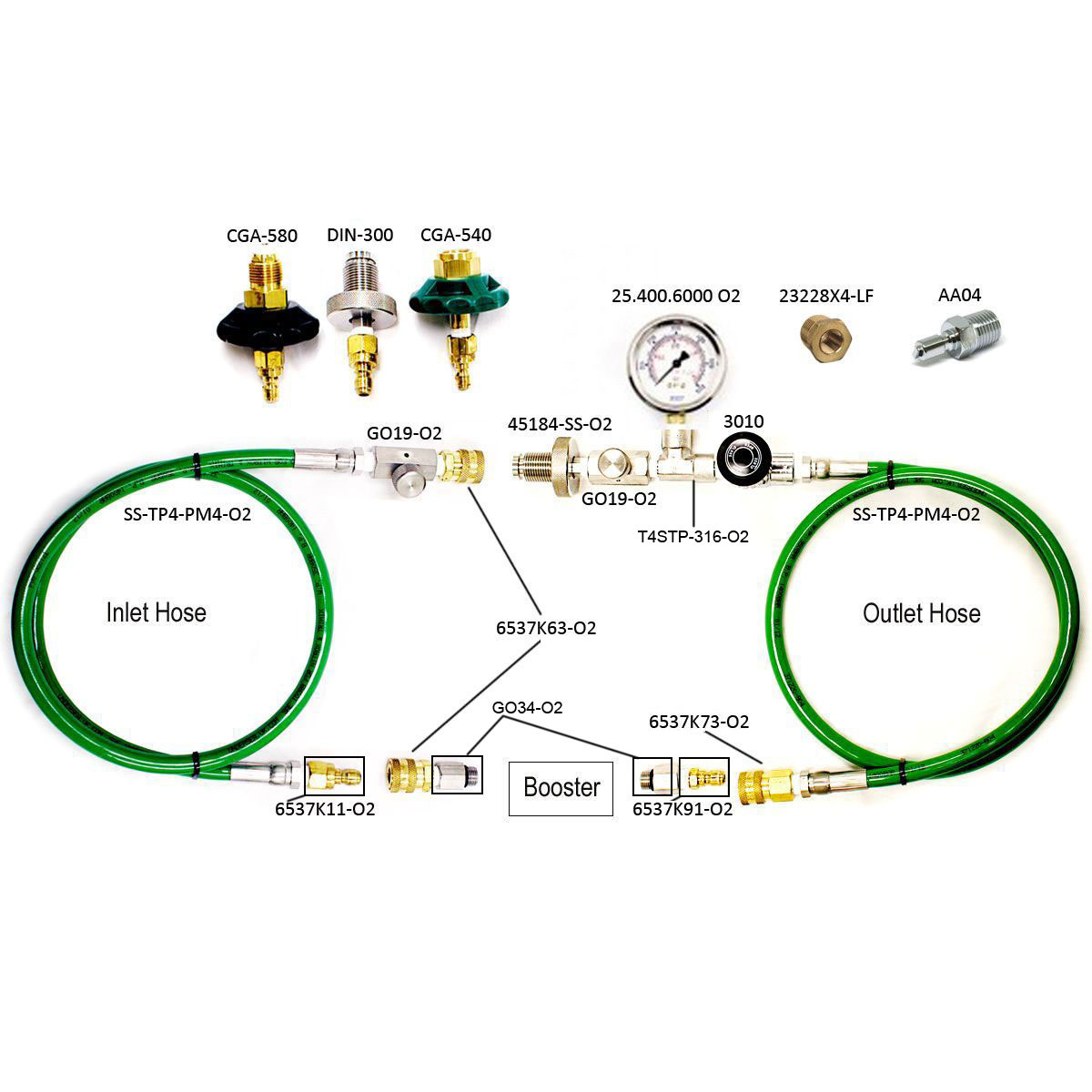

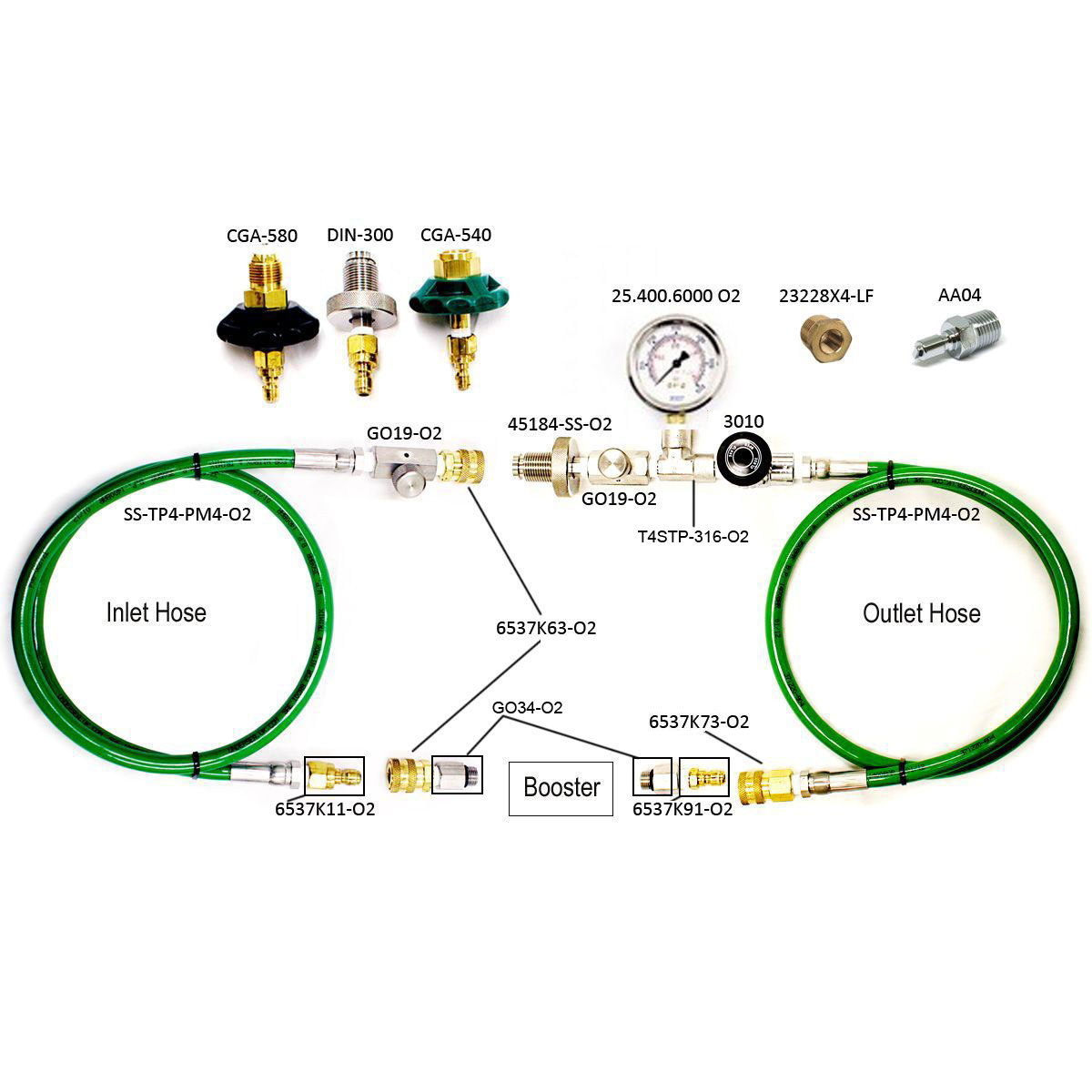

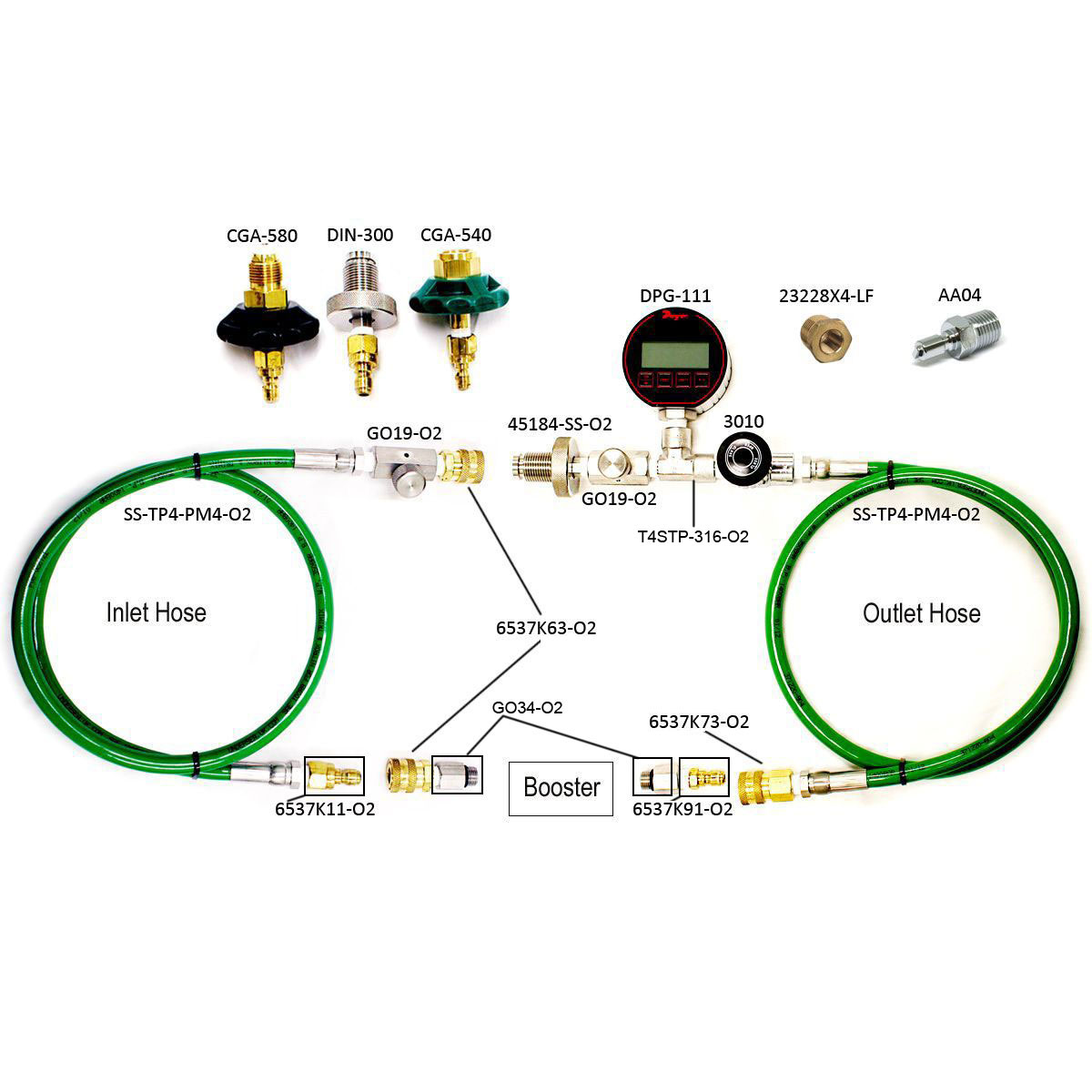

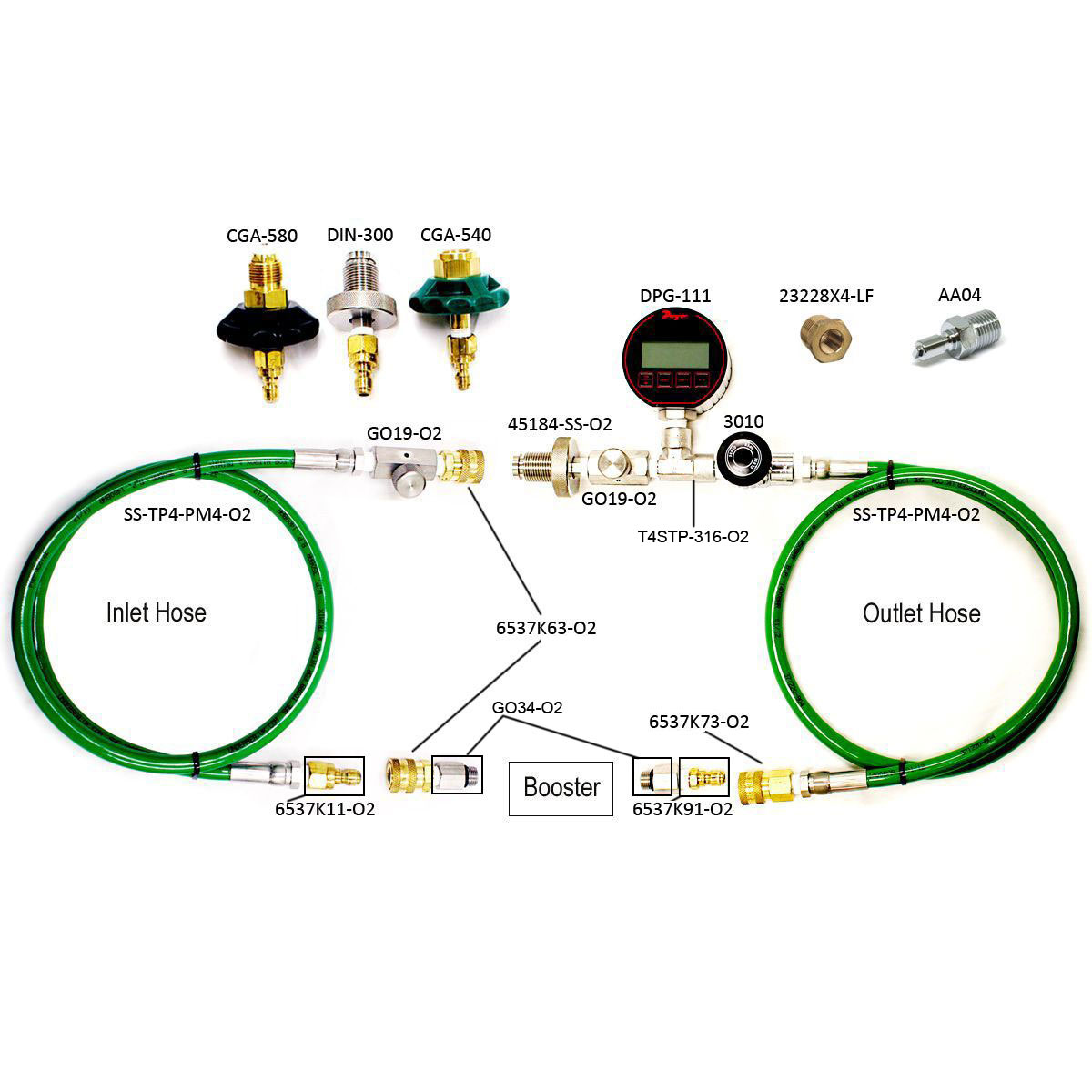

- Particle Filters: Inlet and outlet gas: 5 micron. All stainless steel.

- Guages: Stainless steel tube, solid front 4-1/2" dial size.

- Port Sizes: Inlet and outlet gas: NPT female

- Control Range Adjustment: Inlet minimum: 150 to 850 psi (10-58 bar) cutout. Outlet maximum: 800 to 5000 psi (55-345 bar) cutout. Safety relief (outlet): 800 to 5000 psi (55-345 bar).

- Cooling: With air exhaust to both stages and intercooler.

- Noise: 80 dB range pulses, depending on working pressure (measured at 30 inches from booster).

- Maintenance: Simple seal kit replacement.

- Installation: No special foundation, no tie down required, and no electrical connections.

Booster Specifications

| Drive | 5.75 in (14.6 cm) |

|---|---|

| Ratio | 50:1 |

| Static Outlet (Stall) Pressure | 30 Pa + 2 Ps |

| Max Rated Inlet Pressure | 5000 psi (345 bar) |

| Max Rated Outlet Pressure | 5000 psi (345 bar) |

| Volume per Cycle | 6.2 cu in (0.1016 L) |

| Max Inert Gas Pressure | 9000 psi (621 bar) |

| Max O2 Pressure Output | 5000 psi (345 bar) |

| Min Gas Supply Pressure | 50 psi (3.45 bar) |

| Weight | 115 lb |

| Dimensions | L32" x W14" x H24" |

Haskel OEM/Distributor

Nuvair offers authentic parts and equipment manufactured by Haskel® International, an Ingersoll Rand Business. Beware of inexpensive aftermarket imitations labeled as "replacement," "OEM equivalent," "compatible," or "alternative," as they are not made by Haskel International. Due to size, weight, or specific requirements, some Haskel products may not be available for online purchase, and others may have extended lead times. To confirm compatibility with your existing equipment or to ensure the product meets your needs, please contact the Nuvair Sales Team for ordering assistance by email or phone.