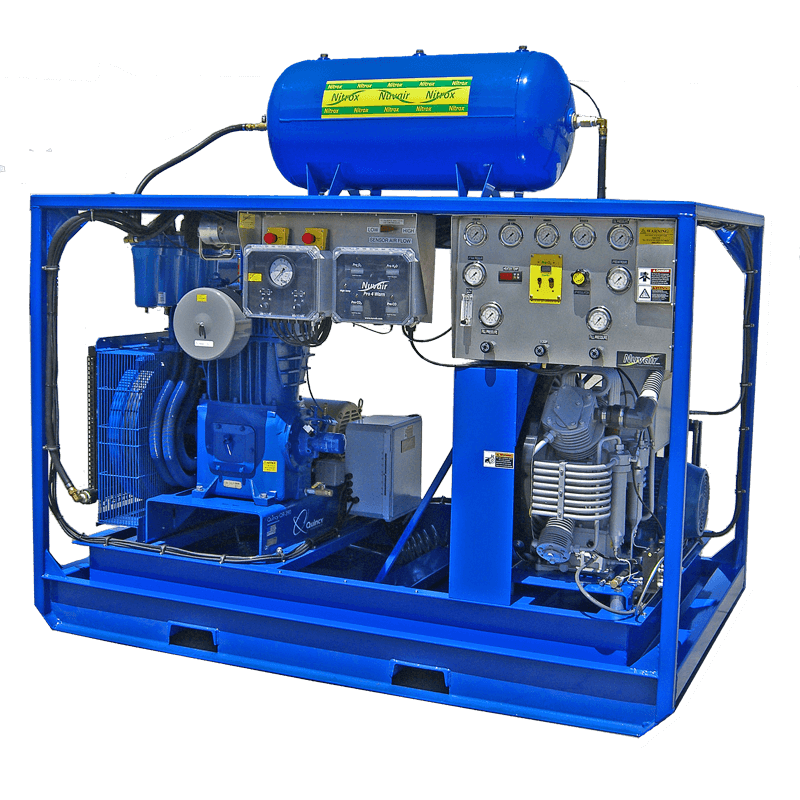

Voyager II, III & IV Heavy Duty Nitrox Generating Systems

Nuvair Voyager II, III & IV are our continuous-duty nitrox producing workhorses. These state-of-the-art turnkey systems come in a silenced enclosure for cool and quiet operation. The control panel is mounted at eye level for easy operation. Fill a standard 80 cu ft cylinder with CGA Grade E quality gas in as little as 4.7 minutes! Available in three models with a variety of power configurations.

The Nuvair Voyager II, II & IV are heavy-duty, turnkey nitrox generating systems that produce nitrox (EANx) or pump air. The system compresses gas with a high-pressure (HP) compressor to fill scuba tanks or storage cylinders. The packages are designed to be fully automatic, with a quieted enclosure for noise reduction and protection from moving parts while it is running.

Using electric power, the heavy-duty Voyagers produce nitrox without the hazards or expense of blending gases with stored high-pressure oxygen (O2). Instead, the system uses a semi-permeable membrane to produce nitrox from air. A portion of the nitrogen in air is separated out, leaving an oxygen enriched nitrox mixture.

The Voyager uses rotary screw low pressure compressors, air/oil aftercoolers, refrigerated air dryers, and filtration to provide the membrane system with a source of clean, pressurized feed air for separation. Air is filtered to CGA Grade D or better air quality prior to entering the membrane system so it will not damage or plug the membrane fibers.

The Voyager membrane system is rated for a maximum feed air pressure of 300 psi (21 bar) and has been configured to work well with the 175 psi (12 bar) maximum pressure delivered by the low-pressure compressor. A back-pressure regulator is used to adjust the amount of air the screw compressor produces to meet the appropriate levels for various percentages of nitrox production (22-40% oxygen).

Used by many federal, state and local agencies, the Nuvair Voyager heavy-duty series is also popular with commercial companies including dive resorts and dive shops around the globe. The Voyager is equipped with a CompAir EK76 low pressure (LP) rotary screw compressor and a Coltri high pressure compressor. Each system can pump out air at 5000 psi (345 bar) and 22-40% enriched air nitrox (EAN) at 3600 psi (250 bar) at 9.3-17 CFM FAD (263-481 L/min).

Features

- Continuous duty compressors

- LP rotary screw compressor with intake modulation producing variable LP air output

- Large LP oil/air cooler with exhaust air fan

- Refrigerated air dryer for extended filter life

- Hankison LP filtration (four filters with a 500-hour element life)

- Nuvair Membrane System

- Permeate and fill O2% analyzers

- Pumps air up to 5000 psi (345 bar) and produces 22-40% nitrox (≤EANx40) at 3600 psi (250 bar)

- Interstage pressure gauges

- 60,000 cu ft HP filtration standard

- LP/HP hour meters

- Digital cabinet temperature gauge

- Digital heater thermostat control

- Easy-to-remove panels for maintenance

- High pressure automatic shutdown

- High temperature automatic shutdown

- Low oil automatic shutdown

- LP and HP automatic condensate drains

Advantages

- Complete state-of-art LP/HP nitrox generating system

- Silenced and enclosed for cool and quiet operation

- Pumps air or nitrox

- Charging rates of 9.3-17 CFM FAD (263-481 L/min)

Options

- Trimix

- Carbon monoxide (CO) analyzer

- Nitrox manager

- 90,000 cu ft filtration upgrade

- Dial-a-pressure shutdown

- High/Low oxygen percentage automatic shutdown

Specifications

| Voyager II, III, IV Model Number |

Voyager II SKU 7044 |

Voyager III SKU 7047 |

Voyager IV SKU 7049 |

|

|---|---|---|---|---|

| Physical Specifications | Height Width Length Weight |

70 in (178 cm) 37 in (94 cm) 68 in (173 cm) 1425 lb (646 kg) |

70 in (178 cm) 37 in (94 cm) 68 in (173 cm) 1474 lb (669 kg) |

70 in (178 cm) 37 in (94 cm) 68 in (173 cm) 1625 lb (737 kg) |

| Full Load Amps | 440-480 V / E3 / 60 Hz 380-415 V / E3 / 60 Hz 208-230 V / E3 / 60 Hz 208-230 V / E1 / 60 Hz |

26 A 23 A 46 A 95 A |

39 A 44.5 A 79 A N/A |

55 A 50 A 95 A N/A |

| LP Compressor | Capacity @ 175 psi | 29 CFM (821 L/min) EK76 |

44 CFM (1250 L/min) EK76 |

59 CFM (1670 L/min) EK76 |

| Horsepower | LP Compressor HP Compressor |

10 hp (7.5 kW) 7.5 hp (5.5 kW) |

15 hp (11 kW) 10 hp (5.5 kW) |

20 hp (15 kW) 15 hp (11 kW) |

| HP Compressor | FAD for 22-40% O2 |

9.3 CFM (263 L/min) | 11 CFM (311 L/min) | 17 CFM (481 L/min) |