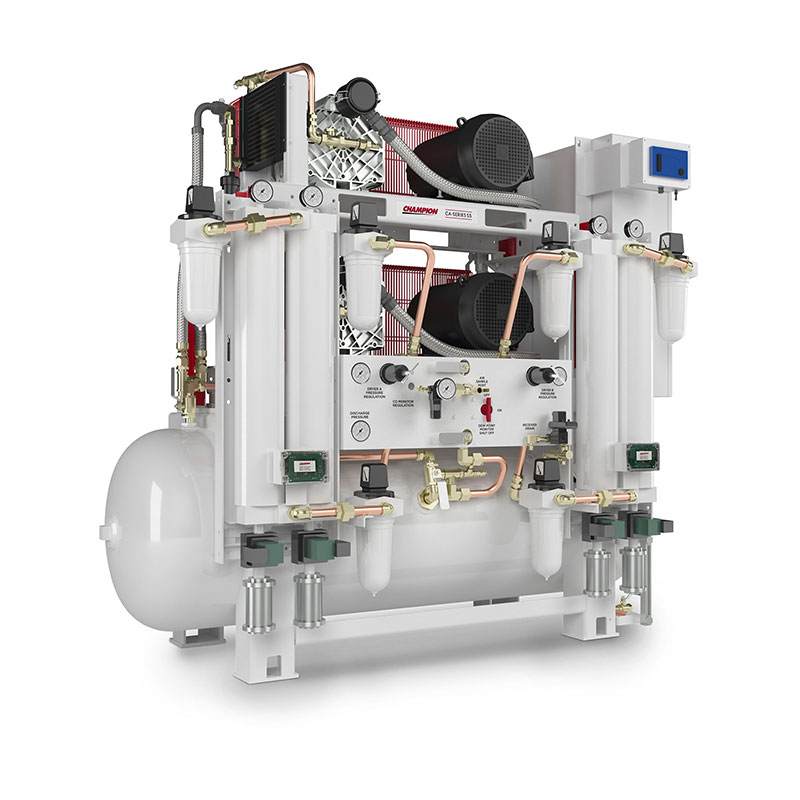

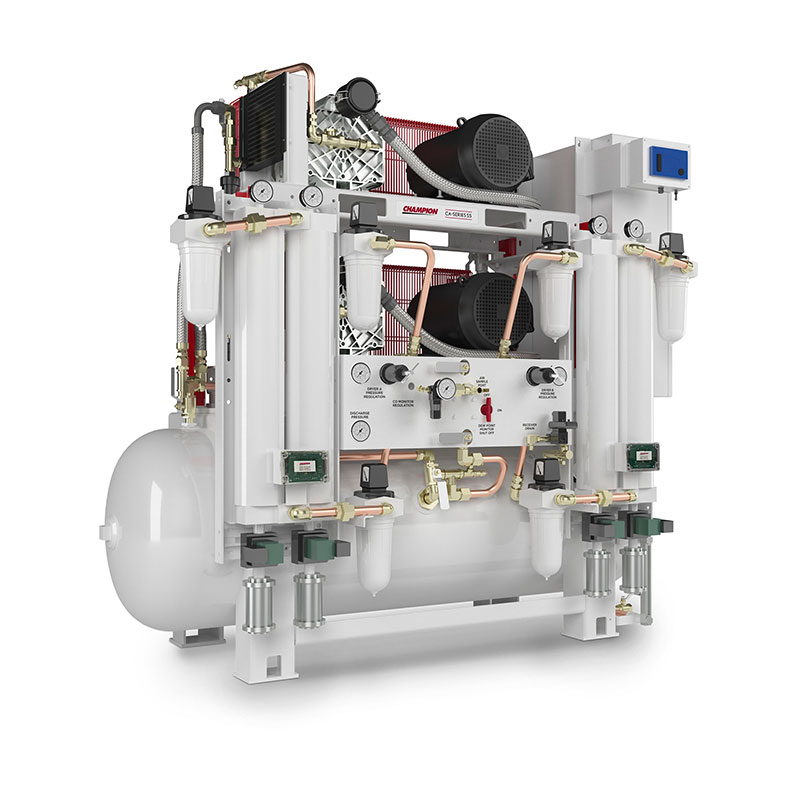

Champion® L-Series Fixed Speed Rotary Screw Compressors: 10–30 hp

The Champion® L-Series L07–L22 are fixed speed, single stage, oil-injected rotary screw compressors from 10-30 hp. These fixed-speed compressors come standard with quiet enclosures, load/no load capacity control, TEFC premium efficient motors, wye delta starters, Pilot™ microprocessor controller, and RotorLube lubricant. Available in base mount or the plug-and-play AirStation™ configuration—compressor mounted on a horizontal 80, 120 or 240 gallon receiver tank with or without a refrigerated air dryer. The L-Series L07–L22 compressors produce 44.5–125.8 ACFM @ 100 psi, 38.7–116.5 ACFM @ 125 psi, or 26.4–92.0 @ 190 psi.

L-Series L07–L22 compressors from Champion® feature more than just the latest compressor technology. They contain the cleanest, simplest, most intuitive machine layouts on the market. Equipped with standard TEFC main motors, wye-delta starters, Pilot™ microprocessor controllers and quiet enclosures, an L-Series unit from Champion is the optimal solution when a feature-rich, simple-to-operate compressor is required.

L-Series L07–L22 compressors are available in base mount or AirStation™ configurations. The plug-and-play AirStation™ is an L-Series compressor mounted on a horizontal receiver tank with or without a refrigerated air dryer. Featuring standard high-end and optional components such as a three-way bypass valve, stainless steel piping, integrated forklift slots and an automatic tank drain, the L-Series AirStation™ is the ideal solution for a compressed air system that requires minimal installation time and cost.

L-Series L07–L22 Features: 10–30 hp

- Belt drive, oil flooded, single stage rotary screw air compressor

- RotorLub 4000 lubricant

- Air-cooled only

- Optional automatic zero-loss condensate drain (with receiver tank selection)

- CRN and ASME rated aftercooler

- Pilot™ microprocessor controller

- Integrated thermostatic thermal mixing valve

- IP54 electrical enclosure

- Load/no load control and timed shutdown

- Moisture separator (shipped loose)

- Mounted and wired wye-delta starter

- Optional ASME receiver tank (80, 120, or 240 gallons)

- Optional mounted non-cycling refrigerated dryer (with receiver tank selection)

- Optional cold coalescing filter (with mounted CRN & CRE dryer)

- Optional three-way bypass valve (with receiver tank and mounted dryer)

- Quiet enclosure

- Second pressure band control for lead/lag operation

- Stainless steel piping (with receiver and mounted tank dryer)

- TEFC main motor

- UL labeled electronics (including C-UL-US open industrial control panel)

- Standard manual tank drain (with receiver tank)

- Voltage

- 200-230/460V (Tri-Volt)

- 208/230/380/460/575V (Dedicated)

- Dryer on AirStation™ has separate electrical connection and voltage

L07–L22 Rotary Screw Compressor Air Delivery, 60 Hz

| Model | HP | kW | Noise Level dB (A) |

Nominal Pressure psi (bar) |

FAD ACFM (m³/min) |

|---|---|---|---|---|---|

| L07 | 10 | 7 | 71 | 100 (6.9) | 44.5 (1.26) |

| 125 (8.6) | 38.7 (1.10) | ||||

| 190 (13.0) | 26.4 (0.75) | ||||

| L11 | 15 | 11 | 71 | 100 (6.9) | 63.1 (1.79) |

| 125 (8.6) | 57.9 (1.64) | ||||

| 190 (13.0) | 44.1 (1.25) | ||||

| L15 | 20 | 15 | 73 | 100 (6.9) | 89.4 (2.53) |

| 125 (8.6) | 83.4 (2.36) | ||||

| 190 (13.0) | 63.1 (1.79) | ||||

| L18 | 25 | 18 | 73 | 100 (6.9) | 110.9 (3.14) |

| 125 (8.6) | 101.9 (2.89) | ||||

| 190 (13.0) | 80.2 (2.27) | ||||

| L22 | 30 | 22 | 71 | 100 (6.9) | 125.8 (3.56) |

| 125 (8.6) | 116.5 (3.30) | ||||

| 190 (13.0) | 92.0 (2.61) |

For AirStation™ specifications, please refer to BROCHURES tab.