Membrane Systems

NITROX MEMBRANE SYSTEMS

Nuvair nitrox generating systems use semi-permeable membranes to produce enriched air nitrox (EAN, EANx, or nitrox). Our nitrox systems produce up to 40% nitrox (EANx40). Used with a high-pressure compressor, the nitrox mixture is compressed for delivery to scuba cylinders or storage tanks for later use. Used with a low-pressure compressor, the nitrox can be used by surface-supplied divers.

When producing EANx40, the Nuvair membrane system is up to 20% more efficient and easier to use than other systems on the market. This can mean savings on the low pressure compressor and membrane as a smaller size system may handle the same job.

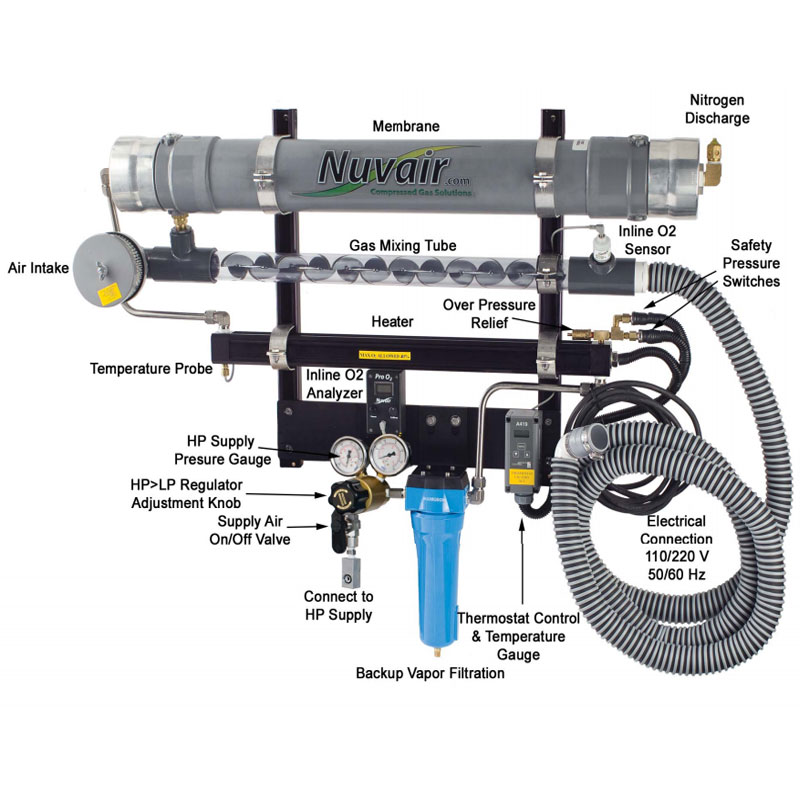

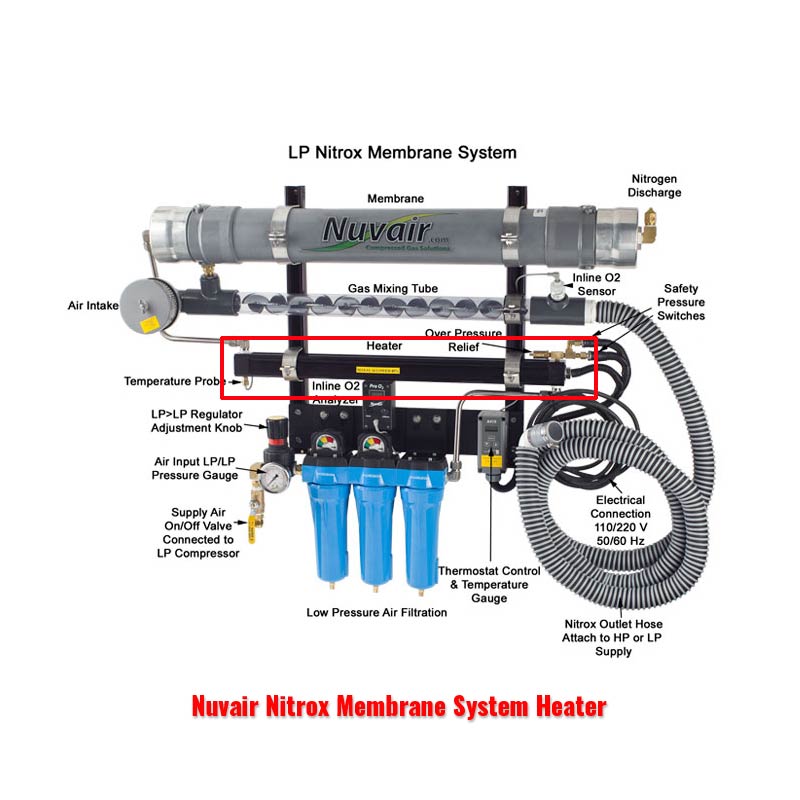

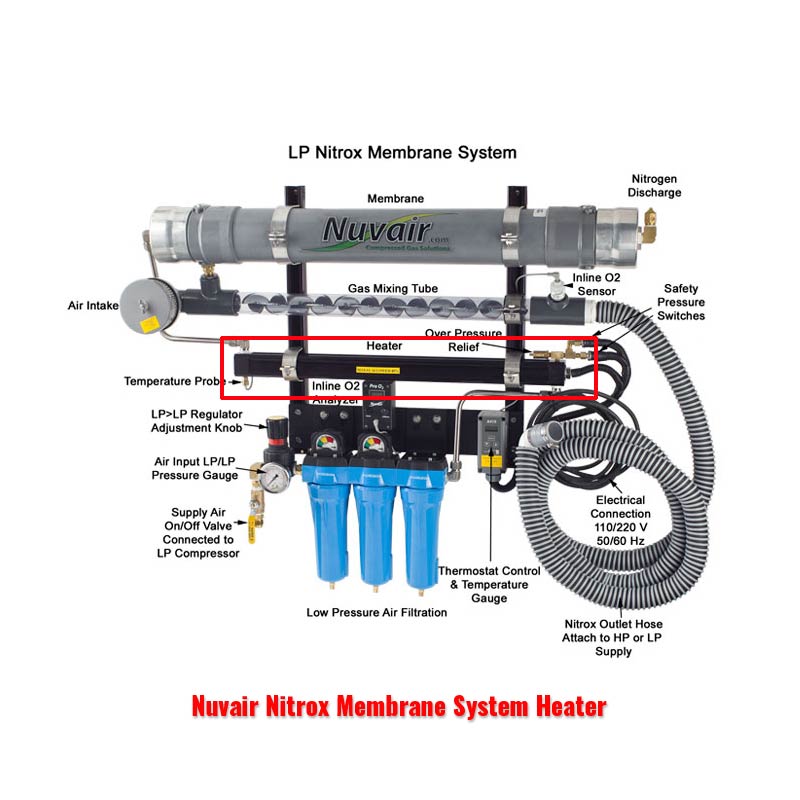

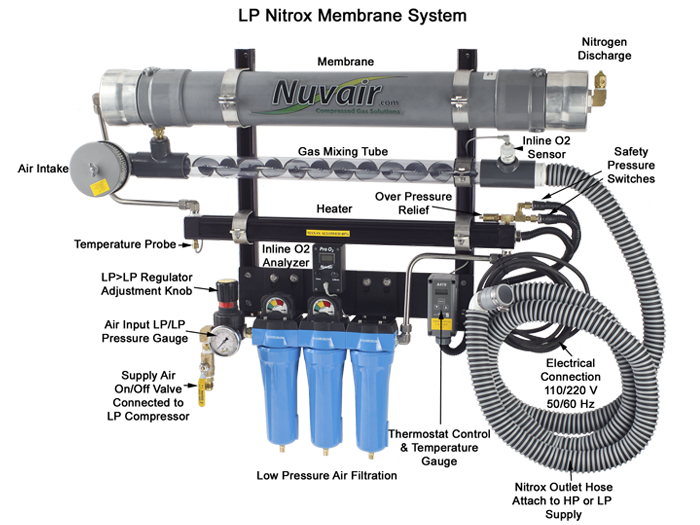

The system requires an air source to supply air to the membrane for separation. This air source (supply air) can be from high-pressure storage tanks or from a low-pressure compressor. First, the supply air pressure must be reduced to 80-300 psi (5.5-21 bar) for use in the membrane. A regulator is used to adjust the input pressure and volume of nitrox to be made.

After passing through the pressure-reducing regulator, air travels through filtration to ensure a proper air quality that will not damage or plug the membrane fibers. After filtration the air is heated to a stable temperature that is constant and optimal for the membrane permeation. This temperature is about 110°F (43°C).

After heating the air enters the membrane, which is made up of thousands of hollow fibers. Oxygen permeates faster than nitrogen through these fibers. A fixed orifice allows the right amount of excess nitrogen to escape. At maximum output, the membrane produces 44% oxygen enriched air called “permeate”.

The permeate exits the membrane through the permeate outlet and enters a static mixing tube that allows permeate and ambient air mixing. This gas mixture is then analyzed with an in-line oxygen analyzer before delivery to the compressor. As the operator increases the input pressure on the regulator, the volume of nitrox produced is increased as well as the percentage of oxygen in the total gas mix. Decreasing input pressure will lower the nitrox percentage mix.

After using your nitrox system you will notice different oxygen percentages match certain input pressures. These input pressures are repeatable. Simply put, if today your compressor pumps EANx36 when the input pressure to the membrane system is at 126 psi (8.68 bar), the next time you want to produce EANx36, just adjust the pressure to 126 psi (8.68 bar). It’s that easy!

Unit shown is for illustrative purposes only.

WHY CHOOSE A NUVAIR NITROX MEMBRANE SYSTEM?

-

![]()

Add to CompareOut of stockNuvair Nitrox Membrane Systems NITROX MEMBRANE

Add to CompareOut of stockNuvair Nitrox Membrane Systems NITROX MEMBRANE - 2400 Watt Heater for Membrane H2400.1$940.00

- 1200 Watt Heater for Membrane H1200.1$576.72

- Gas Mixing Tube Series TUBES

Starting at $452.25