Filtration & Purification

Nuvair filtration and purification products include low pressure (LP) and high pressure (HP) compressor breathing air filters, dyers & coolers, air intake filters, compressor crankcase oil filters, and air/oil separators. The compressed air produced by breathing air systems is hot, wet and dirty. Nuvair filters canisters contain filter elements that remove contaminants like carbon monoxide (CO), water vapor, solids, and oils. With proper equipment operation, testing, and maintenance, you can produce breathing air that meets or exceeds national and international standards.

Agents, Cleansers & Sorbents

Nuvair sells agents, carbons, catalysts, cleansers, desiccants, and sorbents in bulk for refilling repackable filter canisters. These active ingredients purify gas/air by removing contaminants like carbon monoxide (CO), moisture, organics, hydrocarbons, oils, and halogenated solvents.

Products are packaged in various quantities to fit your specific operational needs.

Dryers & Coolers

Humidity in compressed air systems causes corrosion, promotes the growth of microorganisms, and allows condensate to emerge at the point of use—all of which are ongoing dangers for the operational flow because of failing pneumatic controls, increased wear and tear, or because of other disturbances in the production process. Filter life is greatly extended by using refrigerated air dryers and other types of coolers to remove excess humidity from compressed gas. Different types of air dryers (radiator, water-cooled, regfrigerated, and desiccant) all have the same goal—cool the air after compression, reduce the dew point of the gas, and remove excess humidity.

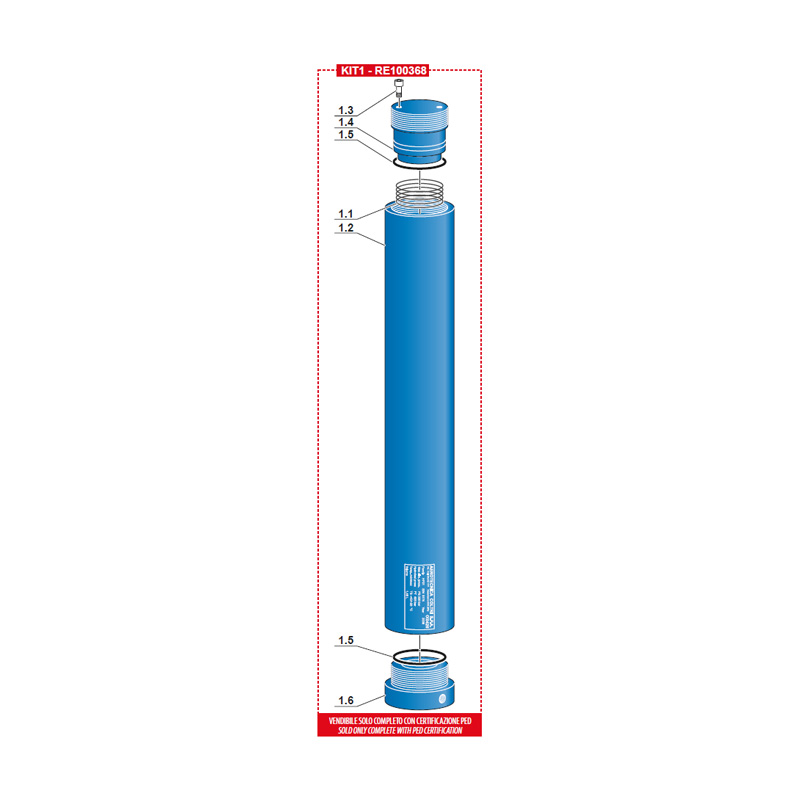

High Pressure Purification Systems

Proper high pressure (HP) filtration requires consideration of many conditions such as compressor size and output in cubic feet per minute (CFM) or liters per minute (L/min), ambient temperature and humidity, compressor type and the amount of oil/condensate that will need to be removed by the filters, required filter life and finally, and desired purity of the gas. Nuvair can size your filtration system to meet any quality standard using our 15-, 25- or 35-inch towers. Larger systems can offer longer filter life, better gas quality, and a cost savings on the filters. This is done by using less expensive filter media for drying and extending the life of the more expensive final filter with active carbon and carbon monoxide (CO) catalyst.

High Pressure Elements

In this category you will find Nuvair's line of HP elements. High pressure (HP) breathing air systems have one or more filter "canisters" (or "towers") containing "elements" (sometimes called "cartridges") that purify gas/air by removing contaminants by filtering out oil, liquid, water, solids, and/or converting carbon monoxide (CO) to carbon dioxide (CO2). HP elements can contain one or more active ingredients like activated carbon, desiccant, molecular sieve, silica gel, or a carbon monoxide catalyst.

Low Pressure Filtration Systems

Nuvair stocks low pressure (LP) air filter systems commonly used in commercial diving and industrial applications. Whether you are looking for an individual filter canister or a multi-stage LP filtration system, Nuvair can fabricate a system to meet your operational needs. Order individual systems online or contact us to customize a filter package.

Low Pressure Elements

Here you will find Nuvair's line of LP elements. Low pressure (LP) air systems can be equipped with one or more filter canisters containing "elements" (sometimes called "cartridges") that filter air by removing contaminants like water, oil, hydrocarbon vapors, and solids. Depending on the level of filtration used, the compressed air produced can be breathed or used in industrial applications.

Intake, Oil, Fuel & Air/Oil Separation

Nuvair stocks air intake, fuel, crankcase oil, and air/oil separation filters for all the rotary screw compressors we service and sell.

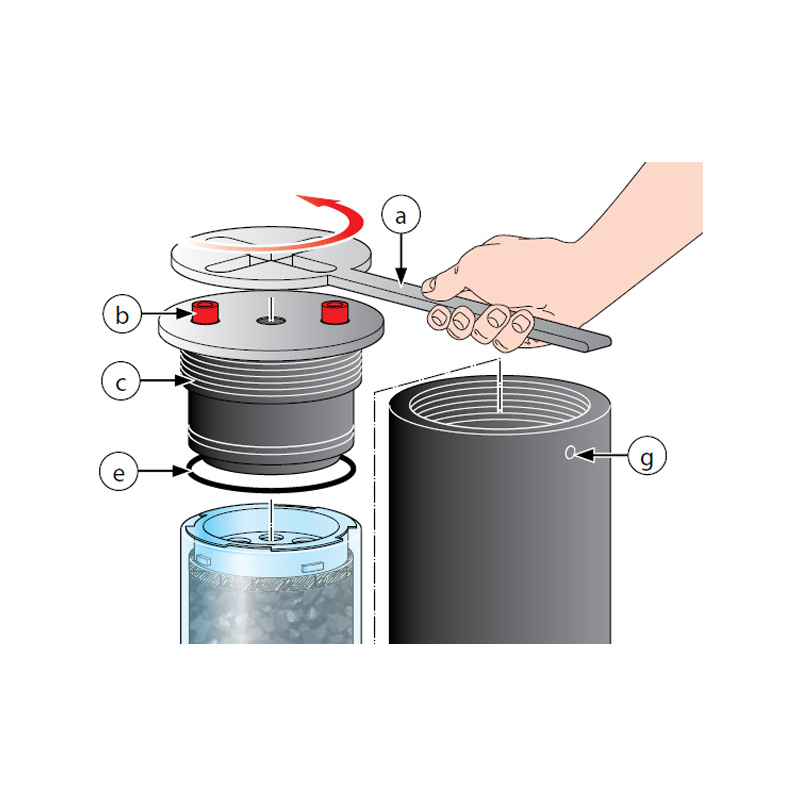

- Coltri Filter Tower Wrench Stainless TL-033$24.63

- Coltri Tornado Refrigerated Air Dryers SC0001302 SERIES

Starting at $5,077.80

- E5-16 Replacement Filter Element E5-16-W$66.81 As low as $53.45

- Nuvair CAN-35 Replacement Drying Filter NUV65677-M-B$70.00 As low as $56.00

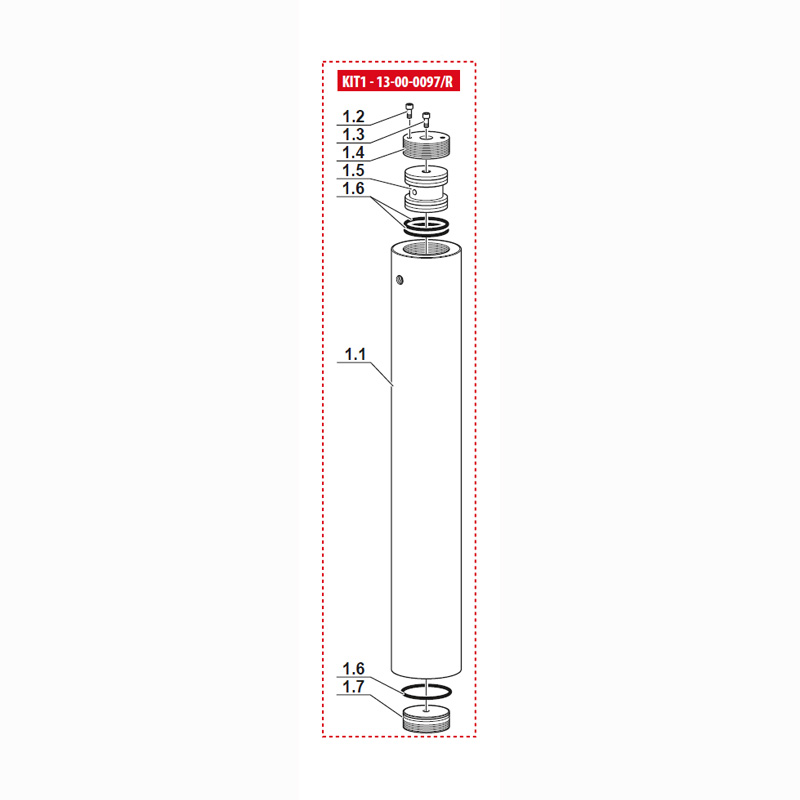

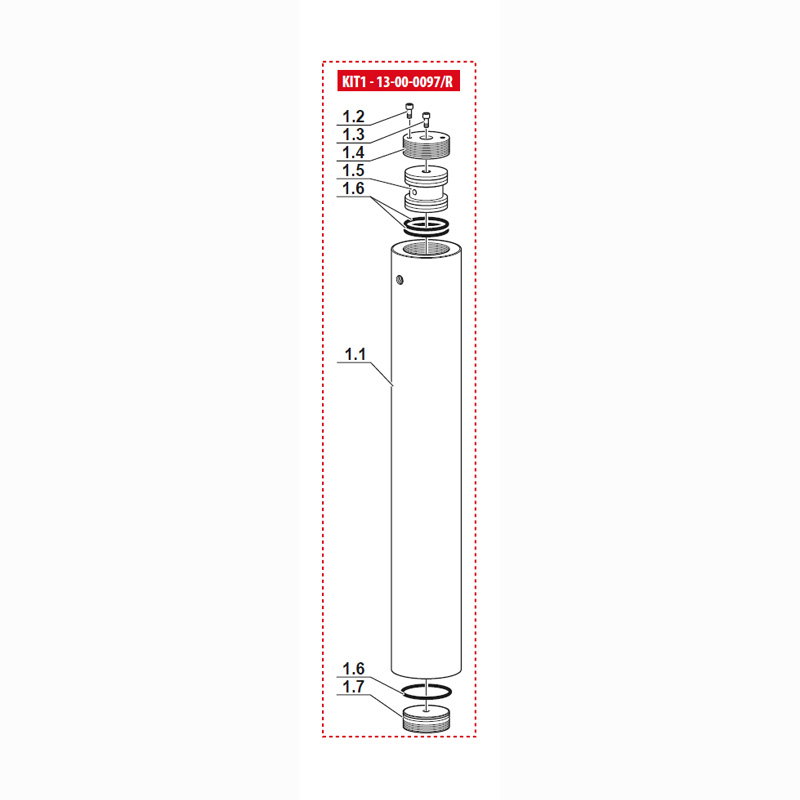

- Coltri Maxifilter Kit 13-00-0097/R$532.14

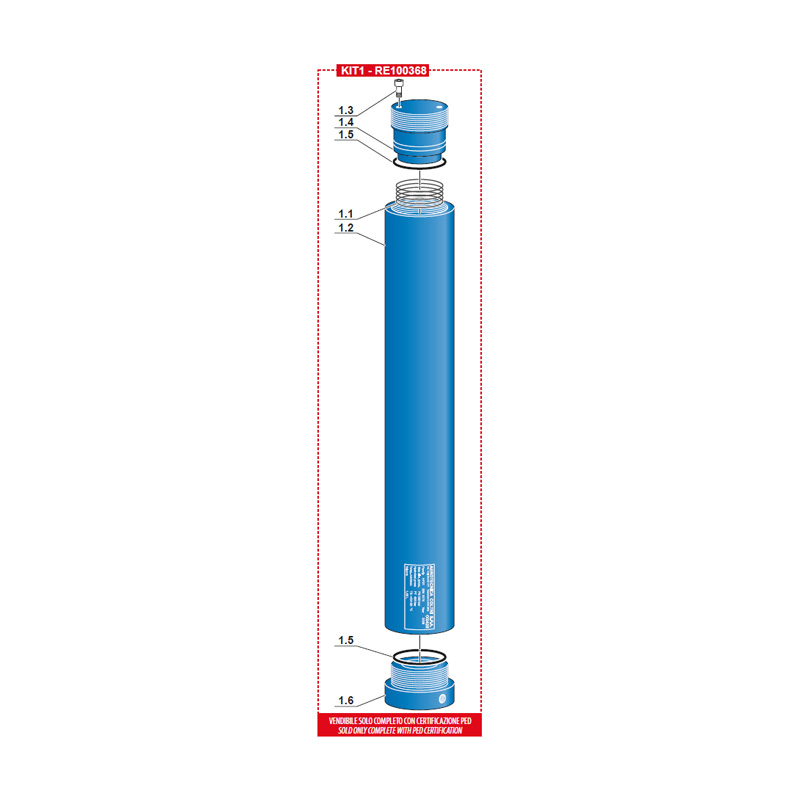

- Repackable Filter Cartridge & Element Series REPACK

Starting at $68.00

- Hankison E5-20 Filter Element E5-20$172.28 As low as $137.82

- Coltri Maxifilter Body 13-00-0097$863.73

-

![]()

Add to CompareOut of stock

Add to CompareOut of stock - Hankison E5-20-05 Filter Element E5-20-05$194.74 As low as $155.79

- E5-20 Replacement Filter Element E5-20-W$89.94 As low as $71.95