Hankison HF Series Air Filters

Filter Specifications: HF1-HF5

| Model No. | HF1-16-4 | HF1-16-4D | HF1-24-6-DGL | HF1-20-4 | HF1-20-4D | HF1-24-6 | HF1-24-6D | HF5-16-4DG | HF5-20-4DG | HF5-24-6DG |

|---|---|---|---|---|---|---|---|---|---|---|

| Item No. | 7426618 | -- | -- | 8000258 | -- | 7426614 | -- | 7425646 | 8000257 | 7426616 |

| Model Size (@ 100 psi) |

16: (35 SCFM) |

16: (35 SCFM) |

16: (35 SCFM) |

20: (60 SCFM) |

20: (60 SCFM) |

24: (100 SCFM) |

24: (100 SCFM) |

16: (35 SCFM) |

20: (60 SCFM) |

24: (100 SCFM) |

| Flow Rating | 35 SCFM [1.00 m³/min] |

35 SCFM [1.00 m³/min] |

35 SCFM [1.00 m³/min] |

60 SCFM [1.72 m³/min] |

60 SCFM [1.72 m³/min] |

100 SCFM [2.9 m³/min] |

100 SCFM [2.9 m³/min] |

35 SCFM [1.00 m³/min] |

60 SCFM [1.72 m³/min] |

100 SCFM [2.9 m³/min] |

| Connection Size (NPTF) |

4: 1/2" |

4: 1/2" |

4: 1/2" |

4: 1/2" |

4: 1/2" |

6: 3/4" |

6: 3/4" |

4: 1/2" |

4: 1/2" |

6: 3/4" |

| Anodized | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Design Pressure | 300 psi | 300 psi | 300 psi | 300 psi | 300 psi | 300 psi | 300 psi | 250 psi | 250 psi | 250 psi |

| Design Temp | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F |

| Height (in) | 11 | 11 | 11 | 13 | 13 | 15 | 15 | 11 | 13 | 15 |

| Width (in) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 4 | 4 | 5 |

| Weight (lb) | 8.1 | 8.1 | 8.1 | 8.5 | 8.5 | 6.3 | 6.3 | 8.1 | 8.5 | 6.3 |

| Certification | None | None | None | None | None | None | None | None | None | None |

| Filter Grade |

1: Oil Vapor Removal | 1: Oil Vapor Removal | 1: Oil Vapor Removal | 1: Oil Vapor Removal | 1: Oil Vapor Removal | 1: Oil Vapor Removal | 1: Oil Vapor Removal | 5: High Eff. Oil Removal | 5: High Eff. Oil Removal | 5: High Eff. Oil Removal |

| LLI Option | No | No | Yes | No | No | No | No | No | No | No |

| Gauge | No | No | Yes | No | No | No | No | G: Diff. Press. Face Gauge | G: Diff. Press. Face Gauge | G: Diff. Press. Face Gauge |

| Drain | Plugged or Manual | D: Auto Drain | D: Auto Drain | Plugged or Manual | D: Auto Drain | Plugged or Manual | D: Auto Drain | D: Auto Drain | D: Auto Drain | D: Auto Drain |

Filter Specifications: HF7-HF11

| Model No. | HF7-16-4DG | HF7-20-4DG | HF7-24-6DG | HF11-16-4-DL | HF11-20-4 | HF11-20-4D | HF11-24-6 | HF11-32-8DL |

|---|---|---|---|---|---|---|---|---|

| Item No. | 7425647 | 8000256 | 7426616 | 3242127 | 3257286 | 3257286 | 3256551 | FL0000576 |

| Model Size (@ 100 psi) |

16: (35 SCFM) |

20: (60 SCFM) |

24: (100 SCFM) |

16: (35 SCFM) |

20: (60 SCFM) |

20: (60 SCFM) |

24: (100 SCFM) |

32: (250 SCFM) |

| Flow Rating | 35 SCFM [1.00 m³/min] |

60 SCFM [1.72 m³/min] |

60 SCFM [1.72 m³/min] |

35 SCFM [1.00 m³/min] |

60 SCFM [1.72 m³/min] |

60 SCFM [1.72 m³/min] |

100 SCFM [2.9 m³/min] |

250 SCFM [7.2 m³/min] |

| Connection Size (NPTF) |

4: 1/2" |

4: 1/2" |

6: 3/4" |

4: 1/2" |

4: 1/2" |

4: 1/2" |

6: 3/4" |

8: 1" |

| Anodized | Yes | Yes | Yes | -- | Yes | Yes | Yes | Yes |

| Design Pressure | 300 psi | 300 psi | 300 psi | 250 psi | 250 psi | 250 psi | 250 psi | 250 psi |

| Design Temp | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F | 150°F |

| Height (in) | 11 | 13 | 15 | 11 | 13 | 13 | 15 | 23 |

| Width (in) | 4 | 4 | 5 | 4 | 4 | 4 | 5 | 6 |

| Weight (lb) | 8.1 | 8.5 | 6.3 | 8.1 | 8.5 | 8.5 | 6.3 | 10.2 |

| Certification | None | None | None | None | None | None | None | None |

| Filter Grade |

1: Oil Vapor Removal | 1: Oil Vapor Removal | 1: Oil Vapor Removal | 11: Mechanical Separator | 11: Mechanical Separator | 11: Mechanical Separator | 11: Mechanical Separator | 11: Mechanical Separator |

| LLI Option | No | No | No | L: Liquid Level Indicator | No | No | No | L: Liquid Level Indicator |

| Gauge | No | No | No | No | No | No | No | No |

| Drain | Plugged or Manual | Plugged or Manual | Plugged or Manual | D: Auto-Drain | Plugged or Manual | D: Auto Drain | Plugged or Manual | D: Auto-Drain |

HF Series Features

| Modular Housings > Manufactured with top quality aluminum, zinc, and steel > Chromated and epoxy powder painted (interior and exterior) for added durability and corrosion resistance > 300 psi (21 bar) maximum working pressure (tested to a 5:1 safety factor) |

| Optional Liquid Level Indicator (LLI) > Allows visual monitoring of liquid level and signals the need for preventative maintenance > Manufactured from thermoset polyurethane, compatible with synthetic lubricants |

| Optional Differential Pressure Gauge > Two color gauge face indicates element change-out based on differential pressure |

| Standard Manual Drain > Condensate drained manually through clockwise adjustment |

| Optional Internal Automatic Drains > Pilot operated, pneumatically actuated to reliably discharge collected liquid > Viton seals - compatible with synthetic lubricants > Inlet screen for additional protection > Discharge fitting threaded to facilitate drain line connection |

| Easy to Install > Modular connections allow housings to be connected in a series easily, while saving space > Optional wall mounting bracket > Can be mounted for left or right entry >New space saving design reduces service clearances |

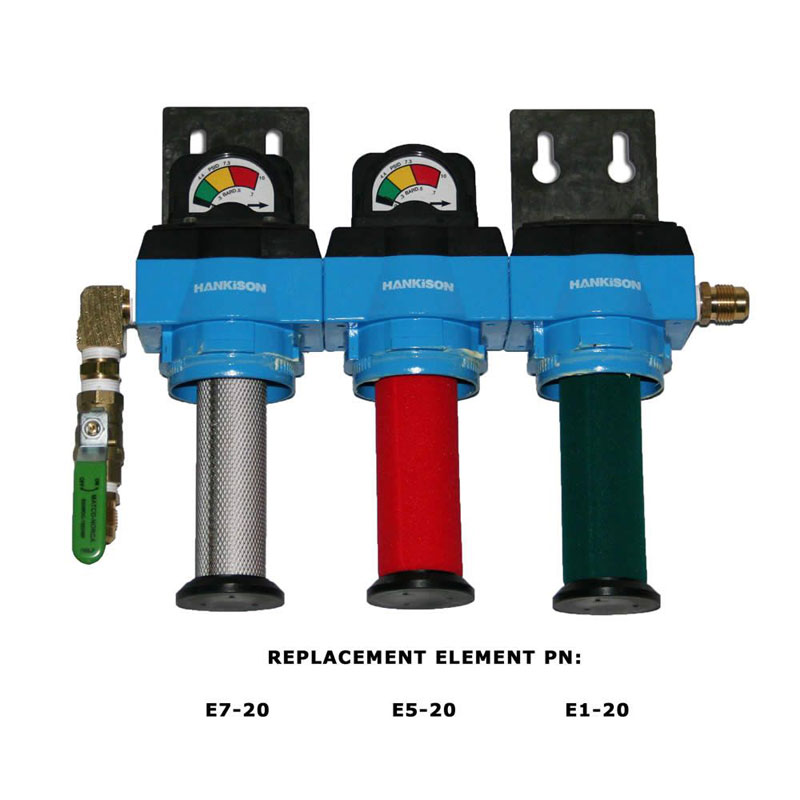

| Easy to Maintain > 1/4 turn, self locking bayonet head to bowl connection (through 1 in) > Push on elements make element replacement quick and easy > Captive O-ring > Ribbed bowls allow use of C spanner > Color coded elements for easy identification |

Filter Element Grades

Grade 1 Filter: Oil Vapor Removal. Removes oil and hydrocarbon vapors normally adsorbed by activated carbon. Removes solid particulate to 0.01 microns with a 0.003 ppm w/w maximum remaining oil content (established in accordance with CAGI standard ADF500 and is based on 100°F inlet temperature). Designed for a 1000 hour life at the rated conditions. Multiple layers of fiber media and screen remove larger particles, pre-filtering the air in the first stage of filtration. In the second stage, multiple layers of bonded, blended fiber media is utilized for fine coalescence. Multiple layers of fine media prevent particle migration.

Grade 5 Filter: High Efficiency Oil Removal. Designed for coalescing fine water and oil aerosols, this filter removes solid particulate to 0.01 microns with a 0.008 ppm w/w maximum remaining oil content (established in accordance with CAGI standard ADF400 and is based on 100°F inlet temperature). The first stage of filtration uses multiple layers of fiber media and screen to remove larger particles, pre-filtering the air, while the second stage utilizes multiple layers of bonded, blended fiber media for fine coalescence.

Grade 7 Filter: Air Line. Provides removal of liquid water and oil. Removes solid particulate to 1.0 micron with a 1.0 ppm w/w maximum remaining oil content (established in accordance with CAGI standard ADF400 and is based on 100°F inlet temperature). The first stage of filtration captures larger particles with alternating layers of fiber media and screen. The second stage of filtration coalesces aerosols and captures solid particles with multiple layers of epoxy bonded, blended fiber media.

Grade 11 Filter: Impact Type Moisture Separator. Moisture separator removes bulk liquid from your system. Two stainless steel orifice tubes provide 10 micron mechanical separation of liquids and solids. Applied downstream of aftercoolers.

Hankison OEM/Distributor

Nuvair offers authentic parts and equipment manufactured by SPX Flow Hankison®. Beware of inexpensive aftermarket imitations labeled as "replacement," "OEM equivalent," "compatible," or "alternative," as they are not made by SPX Flow Hankison. Due to size, weight, specific requirements, or customer demand, some Hankison products may not be available for online purchase, and others may have extended lead times. To confirm compatibility with your existing equipment or to ensure the product meets your needs, please contact the Nuvair Sales Team for ordering assistance by email or phone.