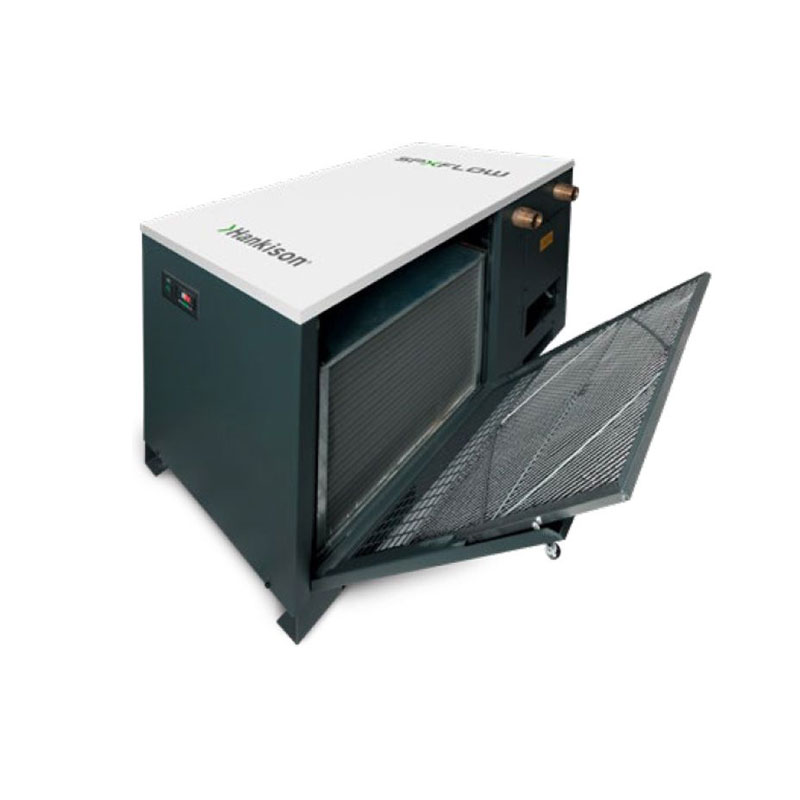

Beko DRYPOINT® RA CT Cycling Refrigeration Dryers

The DRYPOINT RA CT Series of ultra-efficient cycling dryers come with standard BEKOMAT®. Choose from 100 and 125 SCFM models.

With the expansion of the portfolio by DRYPOINT® RA Eco, refrigeration drying can optimally be adjusted to individual requirements: in applications in which stable conditions prevail, DRYPOINT® RA is the number one choice; at a varying volume flow, DRYPOINT® RA Eco series dryers achieve optimum results at a reduced employment of resources.

Specifications

- Required pre-filtration: 1 μm | Recommended post-filtration: .01 μm

- UL/CSA certified: RA CT 20-200: 115V | RA CT 250-500: 230V

- Outlet pressure dew point: Class 4-5 in accordance with ISO 8573-1:2010

- Max. inlet air temperature: 160°F

- Min. / max. ambient temperature: 34°F / 120°F

- Max. inlet pressure: RA CT 75-500: 200 psi

Features & Benefits

Unique Heat Exchanger

Vertical profile allows for minimum pressure drop and self cleans using gravitational force

Eco Series Technology

Maximized engery savings with unique variable speed or cycling technology

Integrated BEKOMAT®

Reliable condensate discharge and maximum energy savings

Maximum Dew Point Stability

Variable compressor and fan operation provide an ultra-stable dew point and no freeze-up guarantee

Maintenance Friendly

The entire range features an open frame that provides easy access to all components

Models

| SKU | Flow Rate (SCFM) |

Connection Size (NPT) |

Pressure Drop |

Operating Voltage |

Dimensions (H×W×D) |

Weight (lb) |

|---|---|---|---|---|---|---|

| 4038911 | 100 | 1-1/4 in | 2.47 | 110V/E1 | 32×19×18 in | 82 |

| 4038912 | 125 | 1-1/4 in | 2.18 | 110V/E1 | 32×19×18 in | 101 |

| 4038915 | 125 | 1-1/4 in | 2.18 | 230V/E1 | 32×19×18 in | 101 |

For price quotes and for information on other DRYPOINT RA CT models not displayed here, please contact the Nuvair sales team.

*How It Works

- Warm, humid compressed air is precooled in the air/air heat exchanger when entering the refrigeration dryer.

- Demand on a compressed air system is often varied, the DRYPOINT RA VSD intelligent controller monitors the incoming conditions and adjusts the compressor and condenser fan speed to the required cooling capacity of the refrigerant system. This saves energy, and over the life of the dryer operating costs decrease.

- The high efficiency condensate separator in the heat exchanger module sustains a high droplet separation of nearly 99%.

- Condensate is discharged from the DRYPOINT RA Eco via the level-controlled BEKOMAT condensate drain.

- Before leaving the dryer, the dried and cold compressed air is reheated in the air-to-air heat exchanger. The relative air humidity is reduced and the cooling capacity is recovered by up to 60%.