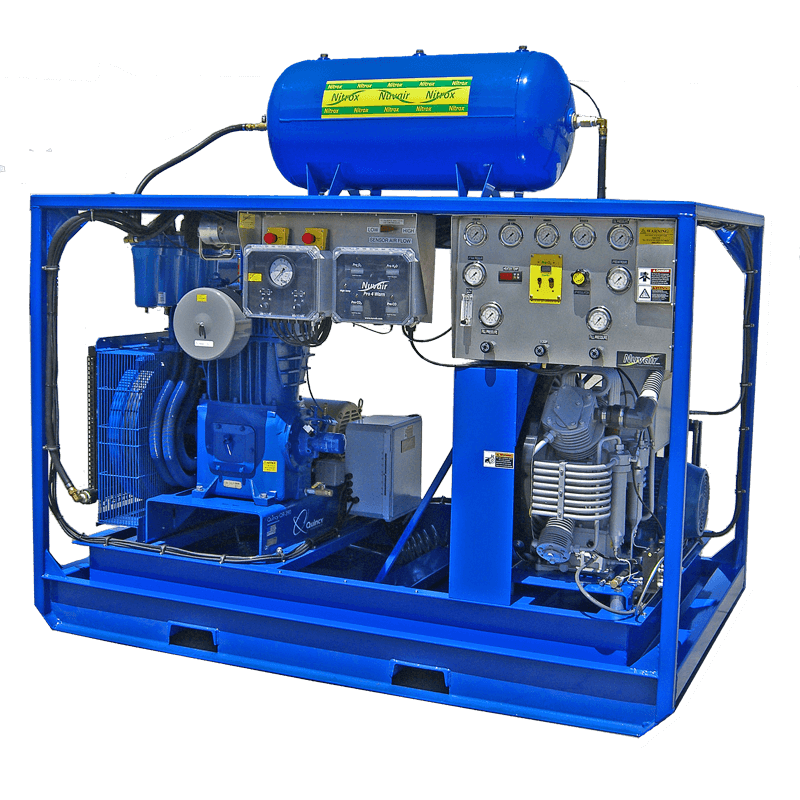

Nuvair LP Nitrox Generator Silent Series

The LP Nitrox Generator series uses a rotary screw compressor to produce enriched air nitrox that is ready for delivery to a high-pressure (HP) compressor for scuba tanks or storage cylinder fills in high demand applications. The package is designed to be fully automatic with an operator overseeing the production to maintain proper nitrox mixtures not to exceed 40% oxygen (EANx40). Available in six models mounted in a silenced cabinet, the nitrox delivery rates range from 17–65 CFM (480–1840 L/min) FAD @ 32% oxygen to 10–38 CFM (280–1019 L/min) FAD @ 40% oxygen.

The low pressure (LP) Nitrox Generator series uses a rotary screw low pressure (LP) compressor, air/oil aftercooler, and filtration to provide the membrane system with a source of clean, pressurized feed air for separation. The air is filtered to CGA Grade D or better air quality prior to entering the membrane system so it will not damage or plug the membrane fibers. Specifications for Grade D air are provided in the User Manual appendix. The membrane system is rated for a maximum feed air pressure of 300 psi (21 bar) and has been configured to work well with the 175 psi (12 bar) maximum pressure delivered by the LP compressor. The model shown is equipped with an optional refrigerated air dryer.

A back-pressure regulator is used to adjust the amount of air the screw compressor produces to meet the appropriate levels for various O2% nitrox production. The air is then heated to a temperature that provides stability over a wide range of ambient conditions, is optimal for membrane permeation, and prevents moisture condensation. The nitrox system allows for efficient and cost-effective nitrox production using electric power, without the hazards or expense of partial-pressure blending with stored high pressure oxygen (O2). Instead, the system uses a semi-permeable membrane to produce nitrox from air. A portion of the nitrogen in air is separated out, leaving an enriched air nitrox mixture. Although it is described as a "nitrox compressor," it can also pump air.

Features

- Silenced cabinet

- Nitrox membrane system with (2) O2 analyzers

- Hankison LP filtration for membrane system

- Refrigerated air dryer for long filter life

- Automatic condensate drains

- Automatic shutdown for high pressure and high temperature

- Soft start

Advantages

- Simplest, most cost-effective nitrox systems available

- Supply LP nitrox containing up to 40% oxygen

- Lower costs, less hassles and hazards compared to O2 blending

- Systems to fit most HP compressors

- Rotary screw LP compressor provides quiet operation and low maintenance

Specifications

| Model | LP280 | LP300 | LP450 | LP600 | LP750 | LP1000 |

|---|---|---|---|---|---|---|

| 230 V / E1 / 60 Hz | 54A 7060.1-EK76-SILENT |

N/A | N/A | N/A | N/A | N/A |

| 230 V / E3 / 60 Hz¹ | N/A | 30A 7060.2-EK76-SILENT |

48A 7061.2-EK76-SILENT |

64A 7062.2-EK76-SILENT |

64A 7063.2-EK100-SILENT |

80A 706X.2-EK100-SILENT |

| 440 V / E3 / 60 Hz | N/A | 16A 7060.3-EK76-SILENT |

21A 7061.3-EK76-SILENT |

33A 7062.3-EK76-SILENT |

33A 7063.3-EK100-SILENT |

40A 706X.3-EK100-SILENT |

| 400 V / E3 / 50 Hz | N/A | 19A 7060.6-EK76-SILENT |

24A 7061.6-EK76-SILENT |

38A 7062.6-EK76-SILENT |

38A 7063.6-EK100-SILENT |

42A 706X.6-EK100-SILENT |

| LP Compressor Capacity @ 175 psi |

29 CFM · 821 L/min | 29 CFM · 821 L/min | 46 CFM · 1303 L/min | 57 CFM · 1614 L/min | 81 CFM · 2294 L/min | 95 CFM · 2690 L/min |

| Rated to Supply FAD for 40% O2 FAD for 36% O2 FAD for 32% O2 |

10 CFM (280 L/min) 12.5 CFM (350 L/min) 17 CFM (480 L/min) |

11 CFM (311 L/min) 14 CFM (396 L/min) 19 CFM (538 L/min) |

16 CFM (450 L/min) 20 CFM (556 L/min) 27.5 CFM (779 L/min) |

22 CFM (623 L/min) 28 CFM (793 L/min) 38 CFM (1076 L/min) |

26.5 CFM (750 L/min) 33.5 CFM (948 L/min) 46 CFM (1301 L/min) |

38 CFM · 1019 L/min 49 CFM · 1387 L/min 65 CFM · 1840 L/min |

| Weight² | 1060 lb · 476 kg | 1050 lb · 476 kg | 1151 lb · 522 kg | 1110 lb · 503 kg | 1250 lb · 567 kg | 1300 lb · 590 kg |

| Dimensions (L x W x H) |

45.5 x 49 x 61 in (116 x 125 x 155 cm) |

|||||

| Membrane Input Operating Pressure Optimum Temperature |

100-175 psi (7-12 bar) 110° ± 5° F (43° ± 3° C) |

|||||

¹For information about 50 Hz models, contact your sales representative.

²Model weight may vary depending on the motor type.